Showroom - Compression Molding

Welcome to Greenerd's Compression Molding Applications Showroom.

We design and build robust equipment intended for maximum up-time in demanding production environments. No matter where your operations are located, we want to help you to compete with reliable equipment and intelligent controls. Call the Greenerd Sales staff at 1-800-877-9110 (within the US) or 1-603-889-4101 (outside the US) or E-mail to discuss your compression molding requirements and discover how easy it is to put our experience to work for you!

|

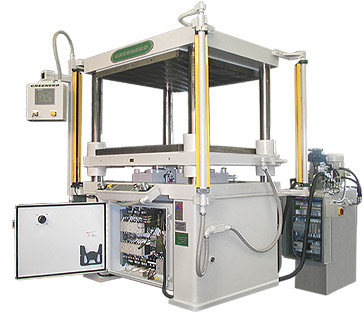

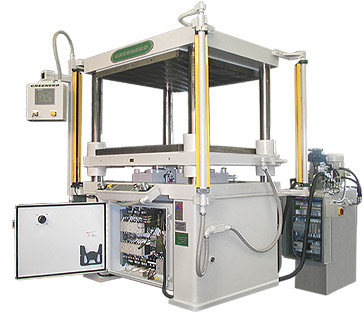

4D-400-86X40-21R24

This pair of 400 ton presses is used to mold SMC into electrical cabinets. Electronic speed control allows for an adjustable pressing speed as well as intermediate and rapid close and open speeds. The Greenerd Press Control allows for both press and mold functions to be programmed and stored. Typical mold functions include initiation and pressure setting for hydraulic actuators within the mold.

Contact Applications Engineering for more information.

E-mail RFQ Form |

Greenerd Press Control Solutions for Compression Molding We can incorporate a Greenerd Electronic Press Control into any of our hydraulic presses. Just imagine how the following control functions can improve productivity in your compression molding operation: - Provide feedback of most press functions, including ram speed, dwell time, operating pressures, distances traveled and other process parameters

- Perform data acquisition and automate serialized production reporting

- Control heating and cooling system set points and ramp rates in conjunction with press movements

- Actuate any operation internal or external to the die, such as those utilizing eject pins, knockouts, or punches

- Provide remote communications from your process via your buisness network or cellular connection. This capability can be harnessed for press monitoring, remote diagnostics, and trouble-shooting by experienced Greenerd service personnel

|

4D-600-120x36-38R

Built for the same process and customer as the 4D-300 below, this press molds SMC into components for the industrial lighting industry. This customer is running their three large, compression molding presses from Greenerd two shifts per day, six days per week.

Contact Applications Engineering for more information.

E-mail RFQ Form |

|

| GG-400-84x84 This unique press is used to mold metal tape under an extensive dwell and pressure cycle. The 400 ton Gib-guided design will withstand an extreme, off-center load of up to 200 tons 33" off-center while maintaining parallelism of 0.015". This press is used to produce a mission-critical component for a military defense contractor. Greenerd was one of only two builders that would quote these extreme specifications. Contact Applications Engineering for more information.

E-mail RFQ Form |

4U-120-42x42-25R3

A 120 ton up-acting press for forming polishing pads for the semiconductor industry. Bed size is 42" x 42". Electric heated platens are controlled to 375° F through the Touchscreen control with temperature feedback from six thermo-couples.

Contact Applications Engineering for more information.

E-mail RFQ Form |

|

|

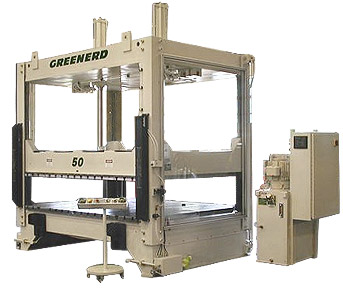

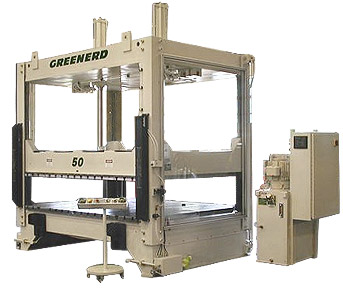

4D-50-110x84-15R3

This 50 ton press has a large bed (110" x 84") for forming automotive heat shields and acoustical panels. The press can accommodate die sets weighing up to 12,000# with integrated QDC equipment. Operator touchscreen interface is built into the fully portable, integrated hydraulic power unit and electrical console.

Contact Applications Engineering for more information.

E-mail RFQ Form |

|

4D-300-72x36-19R

This 300 ton press utilizes a pre-fill hydraulic system to provide rapid advance and return speeds of 700+ ipm for the large platen. The press' industrial computer controls in-die process parameters as well as press performance. Ethernet connectivity enables Greenerd to monitor press performance from 2000 miles away. We helped this customer to increase output by 33% within the first 30 days after installation.

Contact Applications Engineering for more information.

E-mail RFQ Form |

|

| CPA-50 Hydrolair air over oil presses, available in 5 tonnage ranges, from 30 tons to 250 tons. The Hydrolair 4-post, up acting, air over oil presses will hold a vice-like grip for seconds, minutes, or hours, maintaining tonnage for virtually any length of time. With low initial cost and minimal operating costs, the Hydrolair line of presses offers the force of a conventional hydraulic press at a fraction of the cost. Contact Applications Engineering for more information.

E-mail RFQ Form |

|